EMP Solutions

Can your business afford to be vulnerable to an electromagnetic pulse (EMP) attack? What if your business never recovers from the attack? These were questions that the executives and Board of Directors of a public utility asked. Throughout all of the 16 Critical Infrastructure Service Sectors designated by the Department of Homeland Security (DHS), there is a heightened awareness of the potential of an EMP threat. Until recently, protection from the effects of Highaltitude Electromagnetic Pulse (HEMP) and Intentional Electromagnetic Interference (IEMI) have been regarded as a requirement primarily for military and government facilities built for Command, Control, Communications, Computer and Intelligence (C4I). Now, there is growing concern that terrorist and criminal organizations can acquire inexpensive IEMI devices assembled from off-the-shelf materials concealed in suitcases, vehicles or delivered by drone aircraft.

An IEMI attack can bring down a utility, sometimes causing permanent damage to sensitive electronic equipment. In addition, nuclear proliferation among unfriendly nations has raised the concern of a potential HEMP attack from a nuclear device exploded in outer space. Given this very real threat of destructive EMP, the utility management sought out protective solutions from industry experts. ETS‑Lindgren Inc., together with Page Southerland Page, provided the expert solution. The veteran team drew upon decades of experience in design and engineering. ETS‑Lindgren is a recognized world leader in the Radio Frequency (RF) Shielded Enclosure/Anechoic Chamber industry with manufacturing and sales offices around the world. The company is a proven provider of integrated solutions for protection from the effects of EMP events, and the only company whose entire line of EMP protective solutions have been independently tested and certified by the Little Mountain Test Facility at Hill Air Force Base in Ogden, Utah, a facility owned by the US government and managed by Boeing. The EMP protection solution included ETS‑Lindgren’s Red Edge Pulse Protection systems.

RF Shielding Specifications

Of all the threats to a public utility’s required operational computer systems, none is more destructive than an EMP attack. The extremely fast picosecond rise time and voltages of 50 kV or more can permanently destroy unprotected circuitry and erase data in less than the blink of an eye – without leaving a forensic trace. The HEMP/ IEMI shielding, consisting of metal architectural barriers and specially protected points of entry, prevents penetration by externally radiated pulses in free space.

Key features included:

- A hybrid system made up of both modular steel clad panels and steel plate was used. The walls were modular steel clad panels and the floor was fabricated of steel plates welded together to create “six-sided” protection.

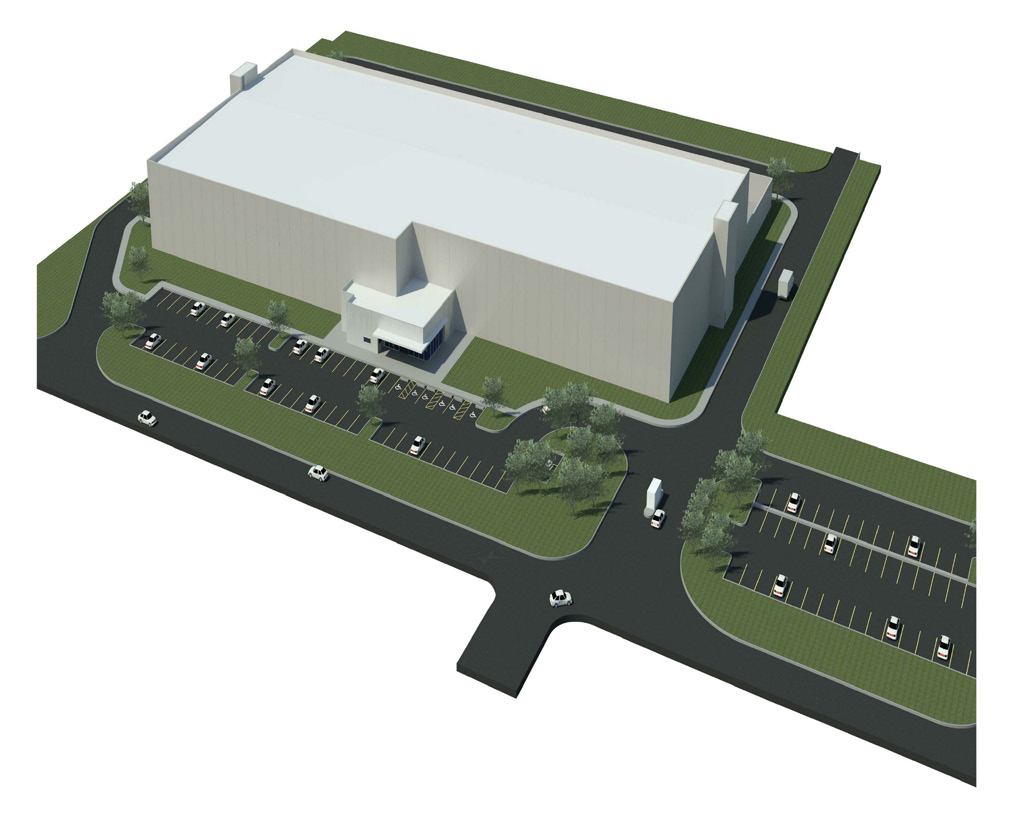

- The facility was a two-story structure and approximately 84,000 square feet.

- HEMP/IEMI shielding performance was tested and verified to meet or exceed the requirements of MIL-STD-188-125.

- The enclosure was approved as compliant with all required structural, fire and electrical codes as well as standards specified for a commercial building.

RF Power and Signal Line Filters

Uniquely designed power and signal line filters blocked conducted EMP from entering the RF shielded enclosure via wiring. These methods can be used to protect an entire building, or a room where critical equipment is consolidated. The RF filters were provided for:

- 6.5 megawatt primary power service.

- Power loads outside of the protected volume.

- All Security, Fire Protection and Communication lines.

RF Penetrations

Various specialty penetrations were provided to ensure secure entry of air, water, data, and fiber optic lines through the RF shielded panels without degrading performance, including:

- Stainless steel drain waveguides were fabricated and welded to steel floor plates to prevent issues with underground points-of-entry (POE) that would become inaccessible after construction.

- Waveguide airflow openings were provided in the shield for conventional radiators and HVAC make-up air.

- High-temperature exhaust waveguides were installed for 2.5 megawatt engine generators.

- Specially designed fiber optic penetrations provided safe entry for data and communications.

Performance Verification

A critical part of the shielding system is the plan to test the shield. Long before any field testing is done, all components that make up the shielding system are laboratory tested and certified before shipment to the project site. Once on site, testing was done in several phases:

- During the assembly of the various walls, floors, etc. to ensure fasteners were tight, welds were done properly, and electrical grounding connections were complete.

- When parts of the enclosure were installed and ready for RF signals. This testing confirmed meeting the target dB reduction level.

- Following completion of the entire enclosure and after surrounding construction was completed. This testing verified the full effectiveness of the system and ensured that there was no damage to the RF shielding.

- Upon installation completion, an independent team from Little Mountain Test Facility conducted modified MIL-STD-188/-125 testing on the facility to document performance.

Grounding

Grounding design is critical to provide pathways for the large currents induced by an HEMP event. Ordinary building safety grounding was coordinated with the high-frequency shield grounding to make sure that no unanticipated route for HEMP currents was available to damage critical equipment inside the shield.

About ETS‑Lindgren

ETS‑Lindgren is an international manufacturer of components and systems that measure, shield, and control electromagnetic and acoustic energy. The company’s products are used for electromagnetic compatibility (EMC), microwave and wireless testing, electromagnetic field (EMF) measurement, radio frequency (RF) personal safety monitoring, magnetic resonance imaging (MRI), and control of acoustic environments.

Headquartered in Cedar Park, Texas, ETS‑Lindgren has manufacturing facilities in North America, Europe, and Asia. Additional information about ETS‑Lindgren is available at www.ets-lindgren.com. Additional information about ETS‑Lindgren’s parent company ESCO and its subsidiaries is available at www.escotechnologies.com.